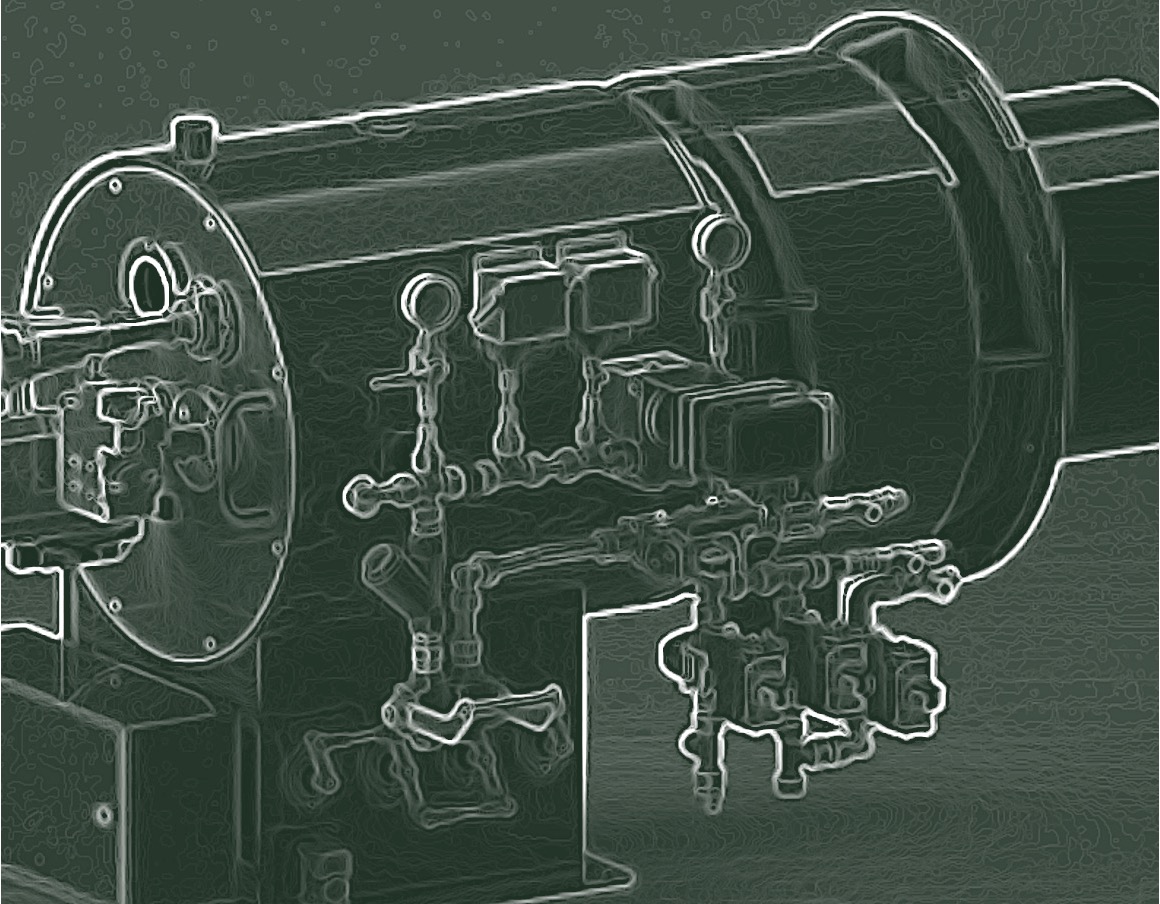

Modular Chemical Recycling plant

Plastic and general waste

Addressing the challenge of converting mixed, contaminated, or hard-to-recycle plastic waste into high-grade circular oil for sustainable feedstock in petrochemical production.

Contact

Resiclo Oy

Company Established Year

Who is this solution for

Info

Available

Looking

Project Status

Looking to expand internationally

Doing business in

Awards

Sustainable Development Goals

Product description

Resiclo’s modular chemical recycling plant is a cutting-edge solution designed to tackle the pressing issue of plastic waste management. By utilizing catalytic thermolysis, the plant can efficiently convert mixed, contaminated, or hard-to-recycle plastics into high-quality circular oil, which serves as a sustainable feedstock for petrochemical production.

The modular design of the plant allows for scalability and flexibility, making it suitable for deployment in various industrial and geographic settings. This innovative technology not only helps in reducing plastic waste but also contributes to lowering emissions, promoting energy efficiency, and facilitating ease of replication.

The Kilpilahti reference plant in Finland, developed in collaboration with Lamor, serves as a testament to the effectiveness of this solution. With an initial capacity of 10,000 tonnes per year and plans for expansion to 40,000 tonnes by 2026, the plant showcases the potential for large-scale impact.

Furthermore, the resulting circular oil produced by the plant meets ISCC+ standards, ensuring its quality and suitability for demanding applications such as food-grade packaging. By aligning with EU regulatory mandates and climate goals, this solution plays a crucial role in bridging the gap in plastic recycling and promoting a more sustainable future.

Key characteristics and environmental benefits

Key Characteristics of Resiclo

-

Uses catalytic thermolysis to process hard-to-recycle plastics

-

Produces circular oil that can replace virgin fossil feedstocks

-

Plants are modular, scalable, and designed for rapid deployment

-

Reference plant operating in Kilpilahti, Finland

-

Output is ISCC+ certified, suitable for food-grade applications

-

Developed in partnership with Lamor for industrial rollout

Environmental Benefits

-

Diverts plastics from landfills and incineration

-

Reduces CO₂ emissions by up to 75% compared to incineration

-

Achieves 40–75% lower carbon impact depending on feedstock quality

-

Delivers over 60% CO₂ reduction with ISCC+ certified circular oil

-

Enables production of food-grade recycled materials

-

Reduces dependency on virgin fossil resources

-

Supports circular economy goals in line with EU regulations

-

Provides a scalable model for sustainable waste management

Looking for

About the Company

Ask about Modular Chemical Recycling plant

Hi there! I’m here to help you quickly understand what this green solution is about — without needing to read the full page.

You can ask me things like:

- What problem does it solve?

- How does it help the environment?

- What makes it different?

Let’s explore together!

You can try asking:

Oops, it seems like you're not a member.

Sign up! It's free. You'll be able to read all the articles you like, download PDFs, and get in contact with the respective owners.

Have an account already? Sign in here