Agraloop™ BioFibre™

Sustainable fashion / Organic waste

Transforming agricultural byproducts into premium-quality natural fibers for sustainable fashion and textile industry.

Contact

Circular Systems

Company Established Year

Who is this solution for

Info

Available

Looking

Project Status

Looking to expand internationally

Doing business in

Awards and certifications

Global Change Award

Recognized Agraloop’s innovation in converting crop waste into valuable fibers

Product description

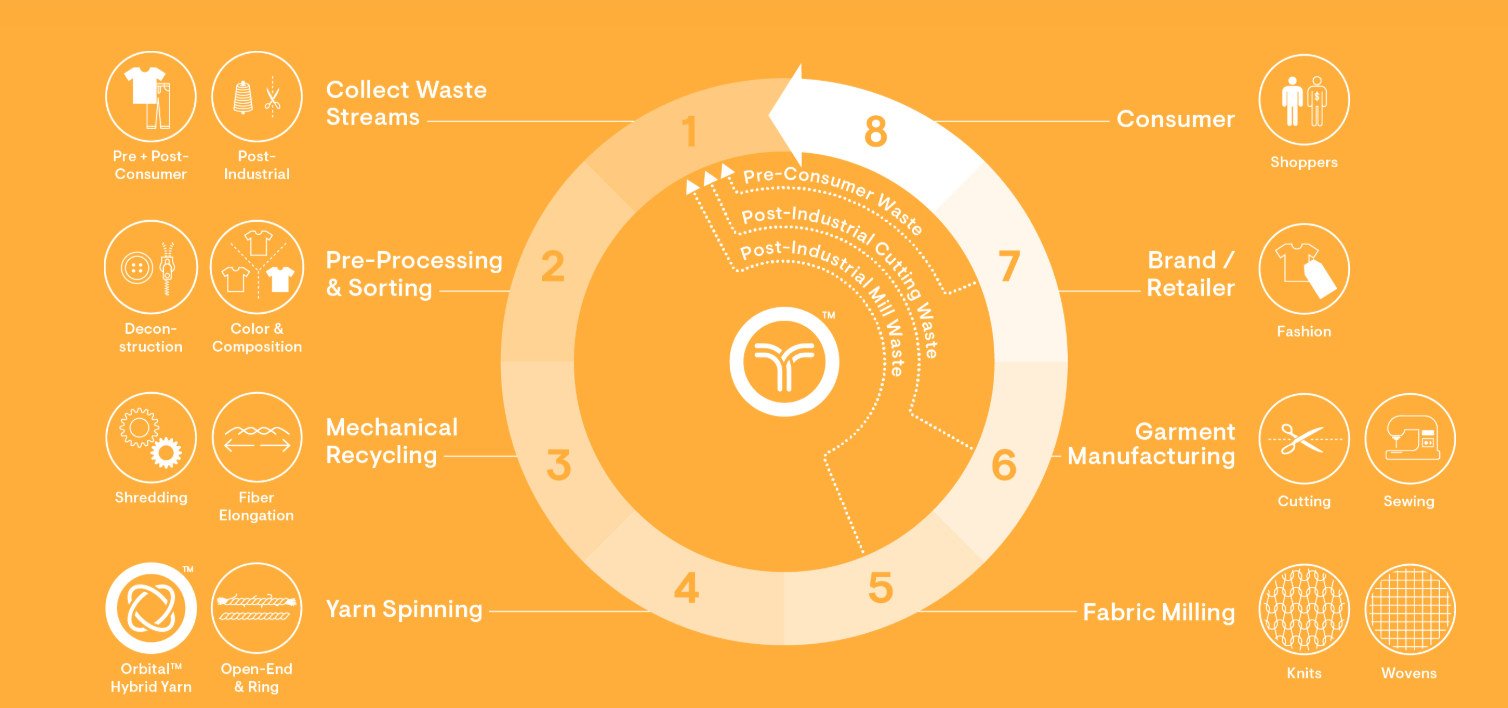

Agraloop™ BioFibre™ is a revolutionary solution in the sustainable fashion and textile industry. It transforms agricultural byproducts, such as hemp/flax stalks, banana leaves, and pineapple waste, into premium-quality natural fibers. Through a proprietary low-water wet-process technique, Agraloop™ purifies cellulose into soft bundles suitable for spinning into yarns. This innovative approach significantly reduces water usage, eutrophication, and CO₂ emissions compared to conventional cotton or linen production methods.

The resulting fibers are versatile and can be used in various fabric types, including jerseys, fleece, denim, canvas, and luxury knits. Brands looking for eco-friendly alternatives can benefit from Agraloop™, which offers a scalable and eco-positive solution. The modular design of the Agraloop™ biorefinery allows for global deployment, facilitating the creation of localized circular supply chains. By utilizing Agraloop™, fashion and textile companies can source natural fibers with a significantly lower environmental impact, promote the valorization of agricultural waste, and align with circular economy and regenerative goals.

Key characteristics and environmental benefits

Key Characteristics

-

Converts agricultural byproducts—like hemp, flax, banana, pineapple, rice straw, and sugarcane bark—into textile-grade natural fiber (BioFibre™)

-

Uses proprietary modular biorefineries with both waterless (DryRefined) and wet-plus-dry (Refined+) processing techniques

-

Produces staple fiber, yarn, and fabrics that integrate with existing textile manufacturing systems

-

Designed as scalable mini-refineries—license-ready for global deployment near farms

-

Supports regenerative farming practices and local feedstock sourcing, enabling local supply chains

🌍 Environmental Benefits

-

Uses significantly less water, reduces eutrophication, and lowers CO₂ emissions compared to conventional cotton, linen, or hemp processing

-

Prevents crop-residue burning/rotting, helping avoid methane, CO₂, and toxic emissions

-

Generates organic soil amendments and plant-based energy, promoting carbon sequestration and nutrient cycling

-

Eliminates need for harmful chemicals like sodium hydroxide, reducing wastewater toxicity

-

Extends the lifetime of crop residues, creating circular material flows and supporting farmer livelihoods

About the Company

Ask about Agraloop™ BioFibre™

Hi there! I’m here to help you quickly understand what this green solution is about — without needing to read the full page.

You can ask me things like:

- What problem does it solve?

- How does it help the environment?

- What makes it different?

Let’s explore together!

You can try asking:

Oops, it seems like you're not a member.

Sign up! It's free. You'll be able to read all the articles you like, download PDFs, and get in contact with the respective owners.

Have an account already? Sign in here